Opportunities for shipbuilding industry

Despite possessing a host of favorable conditions, Vietnam still has much to do to develop a strong domestic shipbuilding industry and secure a firm position in the global market.

According to recent figures from the International Maritime Organization (IMO), more than 90 per cent of global trade is transported by sea. As the government has set a target of 12 per cent trade growth this year and to reach $1 trillion in total trade turnover within the next few years, expanding Vietnam’s shipping fleet and developing a domestic shipbuilding industry have become critical to sustaining stable commercial growth.

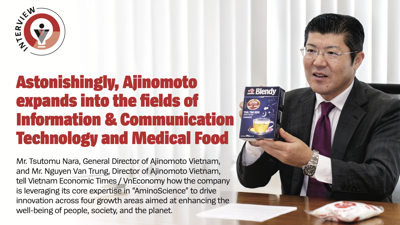

Speaking at the opening ceremony of the 10th VietShip International Exhibition on Shipbuilding and Offshore Technology (VietShip 2025), which kicked off at the National Conference Center in Hanoi on March 5, Deputy Minister of Construction Nguyen Xuan Sang emphasized that Vietnam has targeted economic growth of 8 per cent this year, with key industries, including maritime transport and shipbuilding, playing a crucial role.

Setting sail

According to Mr. Hoang Hong Giang, Deputy Director of the Vietnam Maritime Administration (VMA), Vietnam is currently home to 88 shipbuilding enterprises and 411 facilities specializing in building inland waterway vessels. Vietnam’s current shipbuilding capacity is approximately 3.5 million tons a year, accounting for 0.61 per cent of global market share and employing over 80,000 workers as of the end of 2024.

Among the shipbuilders in Vietnam, the Shipbuilding Industry Corporation (SBIC) is one of the most prominent, operating eight shipyards with an annual new building capacity of 1.3 million tons and a repair capacity of 654,000 tons, building an average of 68 vessels and servicing 304 vessels per year.

Mr. Giang also pointed out that the current capacity is not enough to meet the export needs of Vietnam and there is an urgent need to expand the country’s shipbuilding industry. Of the 1,490 registered vessels in Vietnam as of the end of 2024, over 73 per cent have a gross tonnage of less than 5,000 tons. “The Vietnamese fleet is primarily suited for domestic coastal shipping and short-haul international routes within the region,” he said. “It has yet to compete in the global shipping market. The furthest route currently serviced by Vietnamese vessels is to India.”

He also highlighted that global shipbuilding capacity is currently unable to meet the growing demand for maritime freight. It is estimated that the world will require around 5,284 newly-built ships in 2030, with a total weight of 311.2 million tons. But only a few countries, such as China, South Korea, Japan, and Turkey, have well-developed shipbuilding industries at this time, presenting an opportunity for Vietnamese companies to capture a larger share of the global shipbuilding market.

The VMA forecasts that the country’s shipbuilding capacity for foreign customers could reach 2.7-2.8 million tons a year by 2030, accounting for 0.88-0.9 per cent of global demand.

Dr. Pham Hoai Chung, Chairman of the Member’s Council at SBIC, said shipbuilding is a core industry that contributes to the broader economy by fostering demand in various industrial sectors. Vietnam boasts a nationwide network of shipyards capable of producing a diverse range of vessels to meet both domestic and international market demands. State-owned enterprises (SOEs) such as SBIC and PetroVietnam, along with several foreign-invested shipyards, currently handle the majority of shipbuilding needs.

Despite its relatively small export market share, Vietnam’s shipbuilding sector has successfully developed a range of high-quality vessels, including large-capacity, specialized, and high-tech ships. Over the past two decades, the industry has made significant strides forward, moving from building ships under 3,000 deadweight tons (DWT) to producing bulk carriers of up to 65,000 DWT, 1,800-TEU container ships, 150,000-DWT floating storage and offloading (FSO) units, car carriers for 4,900 vehicles, 104,000-DWT oil tankers, and 13,000-DWT chemical tankers.

Following restructuring efforts, SBIC remains Vietnam’s leading shipbuilding and repair company, operating 25 dry docks and slipways capable of launching vessels ranging from 5,000 to 80,000 DWT.

Vietnam’s demand for maritime transport is expected to grow significantly in the years to come, at around 10 per cent a year to 2030. The goal is for the Vietnamese fleet to increase its share of trade cargo transport while fully meeting domestic transportation needs. Therefore, Dr. Chung believes that the rising demand for shipbuilding will align with the expanding domestic market.

Gaining a foothold

Despite these opportunities and achievements, Mr. Giang also identified several challenges hindering Vietnam’s shipbuilding industry, including scattered investments, outdated production technology, low automation levels, and a reliance on imported materials. Vietnamese shipyards also lag behind foreign-invested enterprises in terms of productivity and competitiveness.

Therefore, despite having 88 shipbuilding companies, Vietnam’s specialized infrastructure for the industry remains limited. Nationwide, there are only 19 docks / slipways for building and repairing ships ranging from 5,000 to 400,000 tons, 17 slipways for vessels between 6,500 and 70,000 tons, and just one modern ship lift capable of handling ships up to 70,000 tons. “Meticulous precision is required to apply modern shipbuilding technology, much like manufacturing an automobile,” Mr. Giang explained. “Slipways or floating docks cannot be used for this purpose. A ship lift, similar to an elevator, is necessary, but Vietnam has only one such facility in the entire country.”

In addition to the lack of shipbuilding infrastructure, he added that the local shipbuilding industry has not yet mastered the production of any major component of the process, as the country lacks a developed support industry and primarily provides labor-intensive services.

Dr. Chung said his company, despite being the biggest domestic shipbuilder, is only operating at around 50-60 per cent of design capacity due to insufficient investment in infrastructure and technology.

To overcome these issues, Mr. Giang, drawing from the experience of other countries with developed shipbuilding industries, emphasized the need for SOEs to take the lead, with preferential loans, contract guarantees, and policy support offered to attract and train a highly-skilled workforce. Tax incentives and financial assistance are also necessary to boost the industry’s growth.

The government should designate specific coastal and riverfront areas for shipbuilding and repair facilities, exempt shipbuilding enterprises from land rental fees, and establish dedicated shipbuilding industrial parks in key cities and provinces such as Hai Phong and Quang Ninh in Vietnam’s northern region and Ba Ria-Vung Tau in the southern region.

Regarding capital investment and the development of support industries, experts recommend that Vietnam identify its niche and the right market segment within the global shipbuilding industry.

While countries like China focus on building large vessels with relatively-advanced technology, South Korea and Japan specialize in high-tech, large-tonnage ships. Vietnam, in contrast, could carve out a position by targeting mid-sized and smaller cargo ships, allowing it to establish a foothold and secure the necessary funding for further development.

Preparing for the future

Looking at the future of shipbuilding, many countries are setting ambitious goals to become hubs for “green” shipbuilding by 2030 and secure a fully green-powered domestic fleet by 2050.

To stay competitive amid this global shift, Mr. Giang proposed a series of measures for Vietnam, including a long-term strategic roadmap for its shipbuilding industry to ensure sustainable growth.

In terms of financial solutions, the VMA suggested adding shipbuilding enterprises to the priority list for industrial support incentives, offering tax exemptions and reductions, providing preferential loans, and establishing a fund for technological innovation and infrastructure development.

According to Mr. Sivert Skårn, General Director of Vard Vung Tau, one of the most prominent foreign shipbuilders in Vietnam, the global shipbuilding industry is increasingly focusing on developing and adopting new technological solutions that are environmentally-friendly, enhance sustainability, and utilize clean fuel. The Norwegian shipbuilding group has already mastered these technologies and is ready to implement them at its production facility in Vietnam.

"We have just completed an expansion of our shipyard in Vietnam, driven by our belief in the future of the country’s shipbuilding industry and its strong export potential."

Mr. SIVERT SKÅRN, General Director of Vard Vietnam

However, he added that adopting these advanced technologies and techniques requires government coordination and policy support, along with investment incentives to attract foreign shipbuilders to introduce these innovations in Vietnam.

![[Interactive]: Economic overview - April 2025](https://media.vneconomy.vn/400x225/images/upload/2025/05/06/5a245778-67b1-4874-a8dc-21f8cfed62a6.png)